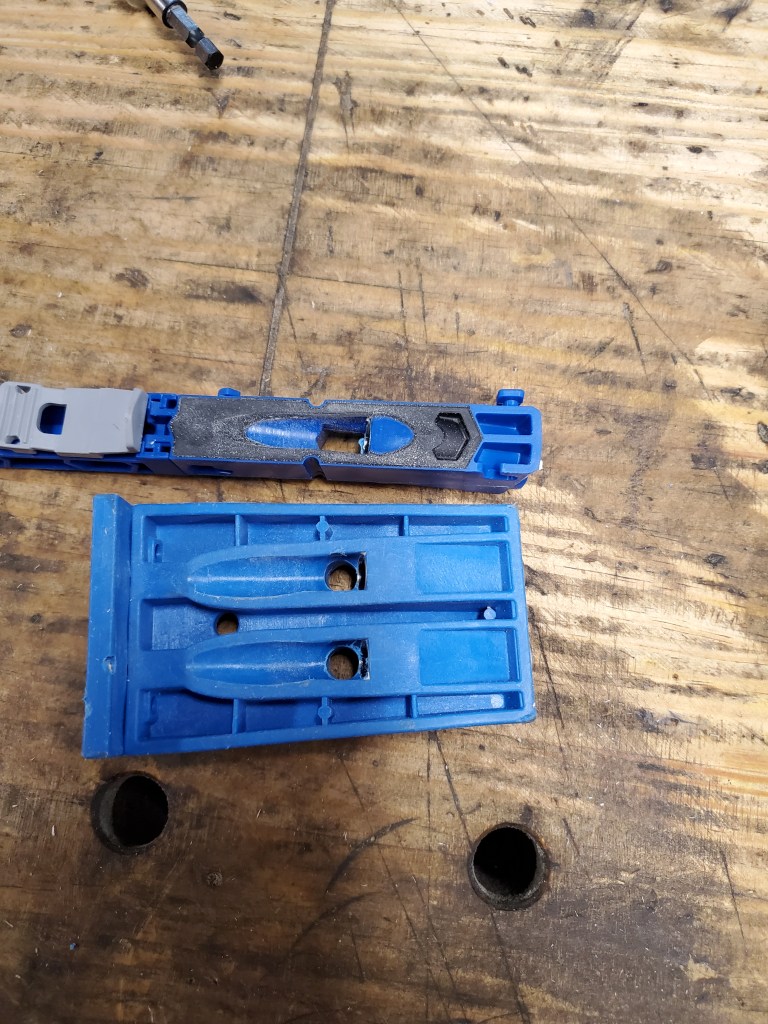

A couple of weeks ago, I received the latest issue of Popular Woodworking Magazine. Inside was a photo of a new fixture made by Woodyah that hit the market. It was a piece of plastic you put on your hand plane to make your tote tilt at an angle for using it as a shooting board plane. I thought it was pretty cool, so I went online and ordered it.

The fixture came in the mail in a few days, and I took a look at it. It’s made with a 3D printer, so it’s made precisely to fit and it comes with its own hardware. You just need to use your original front tote screw to screw the fixture onto your plane in the front. I downloaded the instructions when I bought the fixture, so I knew how to put it on before I received it.

Once everything is attached, the tote feels really comfortable in your hand, and it’s simple to install.

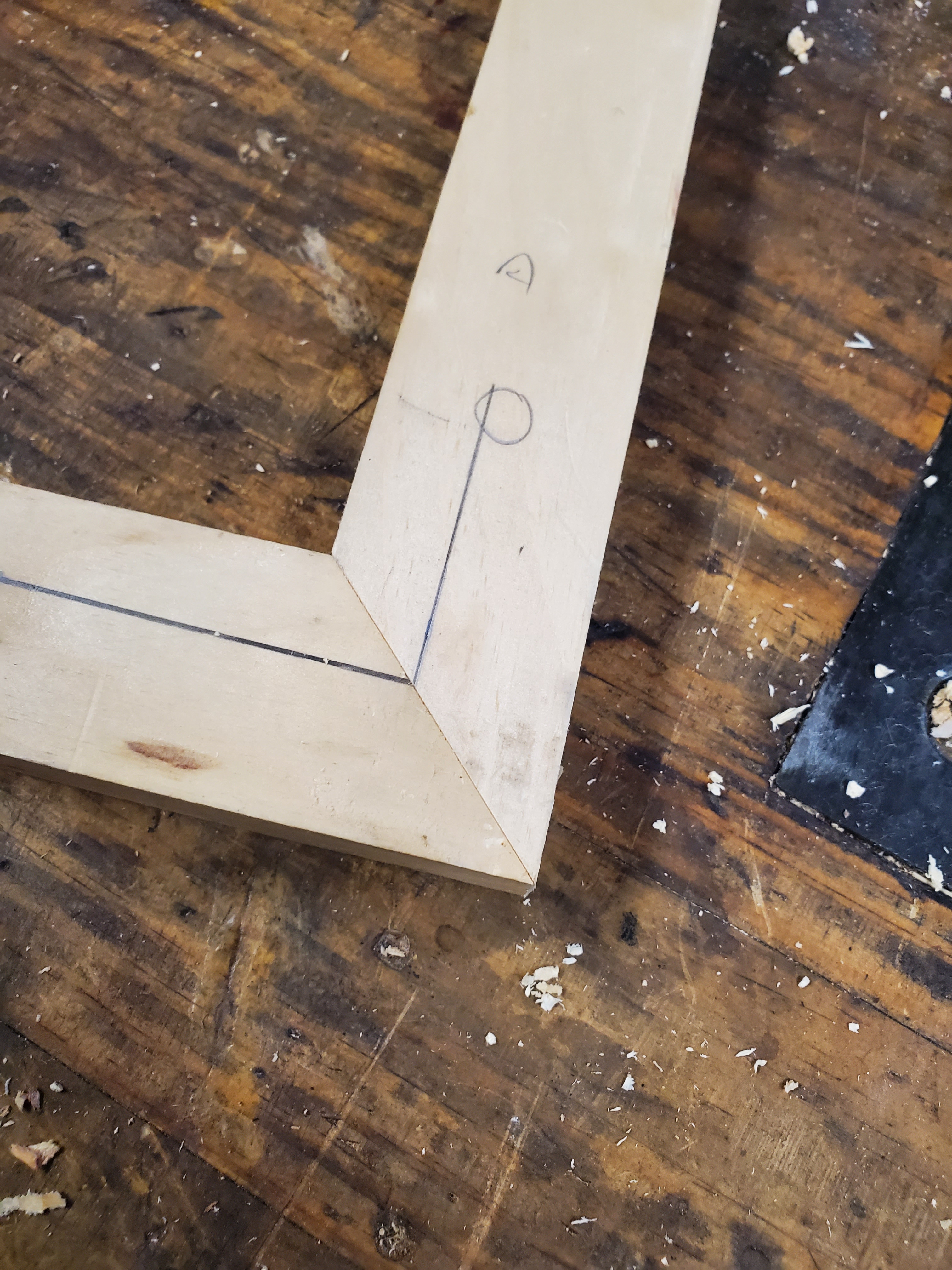

The next thing I needed to do was make a shooting board to go with the plane. I had a scrap of 1/2″ prefinished cabinet grade plywood and some poplar stock (I should have used maple, but I didn’t have any lying around.) The shooting board base is about 10″ wide by 15″ long. The length of the shooting board was simply determined by the overall length of plywood I had, knowing I had to cut it in half.

The parts were pinned and glued together, and I made sure that the side of the plane rode nicely against the thin rail of the shooting board.

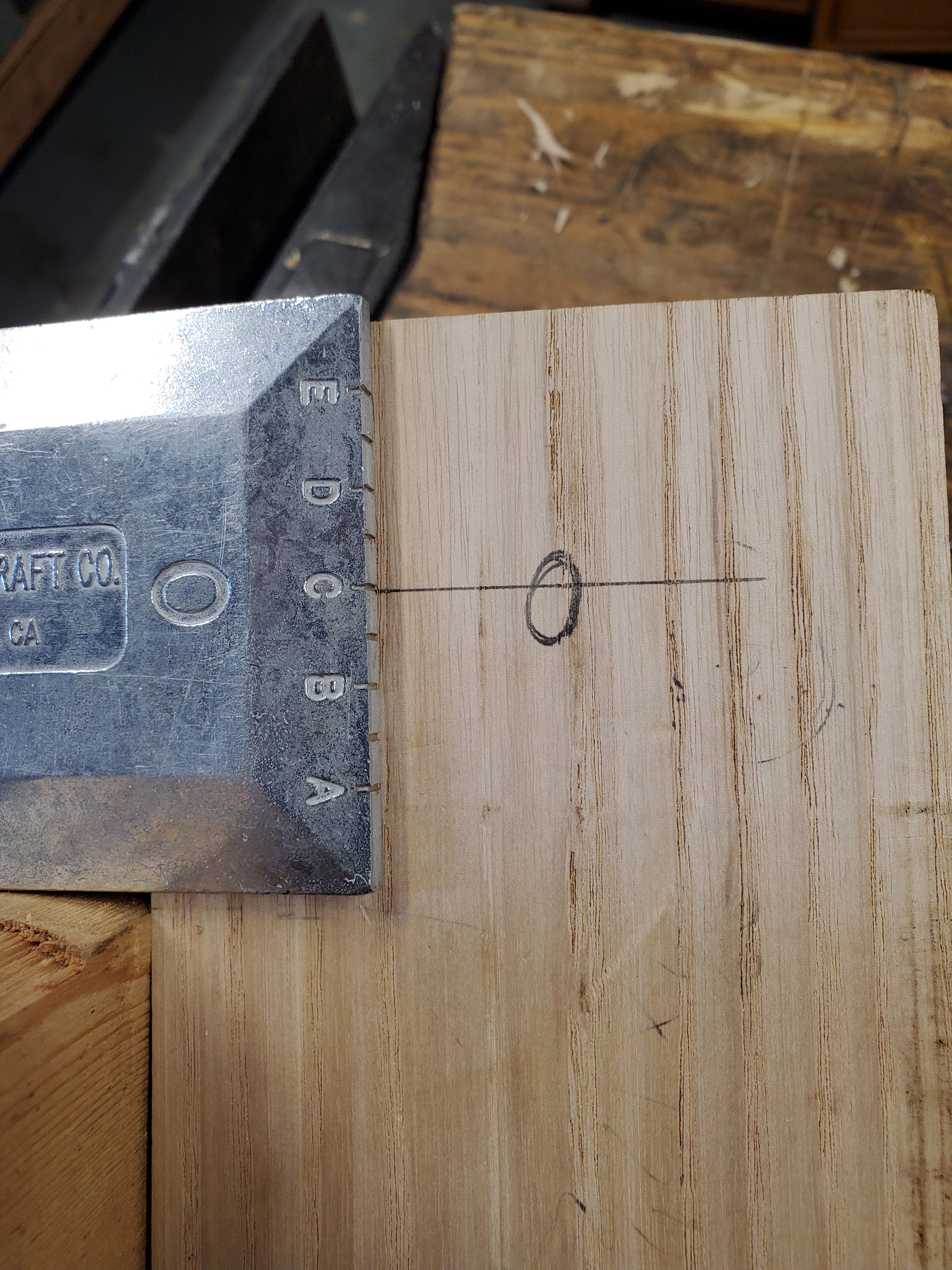

Everything worked, but I needed to make sure it was accurate. I checked the squareness of the side of my plane against the bed, and it was just a touch off.

I took the plane over to my oscillating edge sander and fettled the bed first, then flipped it over on its side to fettle the side perfectly 90 degrees.

Taking the plane back to the shooting board, I made sure the bottom of the bed was a perfect 90 degrees to the face of the shooting board.

I then set the blade and tried it out. It worked well with a little bit of practice. Because there is only one point of contact between the side of the bed and the rail, I had to take slow and purposeful strokes to make sure I got a smooth cut. If I tried to use the plane fast, the plane would rock back and forth, producing an inaccurate cut.

I wanted to try shaving miter cuts with the shooting board. At first, I thought about making some sort of fixture that would attach to the base with dowels or some other mechanism. Then I thought to myself not to reinvent the wheel when I saw a plastic speed square in my tool cabinet. I simply placed the square on my shooting board where it needed to be in order to produce a perfect 45-degree angle and clamped it in place with a couple of C clamps. Then I cut a witness mark on the fence and square so I knew where it went the next time I used it.

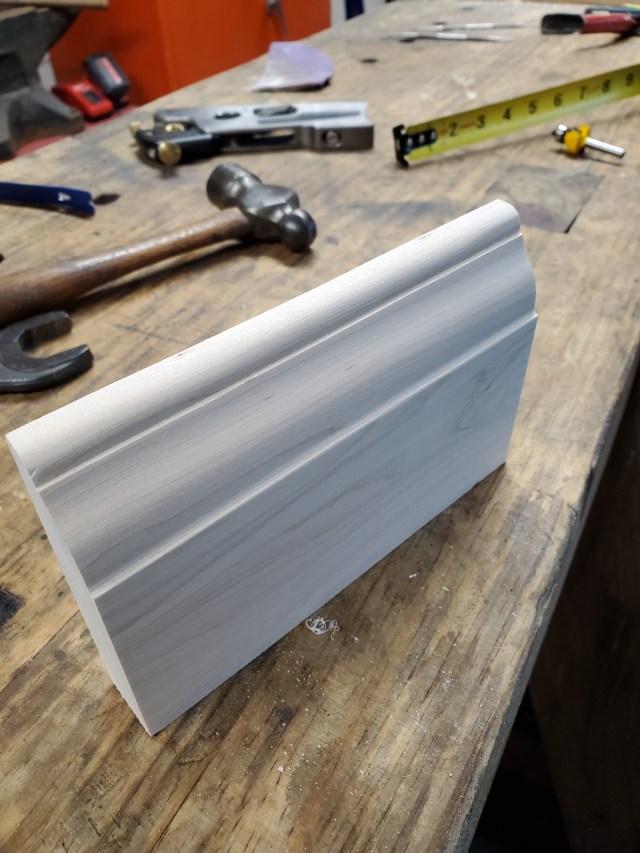

With a sharp blade, the plane was cutting incredibly clean and accurate shavings. They looked like chocolate shavings you find on fancy desserts.

Fortunately, this is the plane that I wrote an article for Quercus Magazine last year, so I’m glad I now have a use for it.