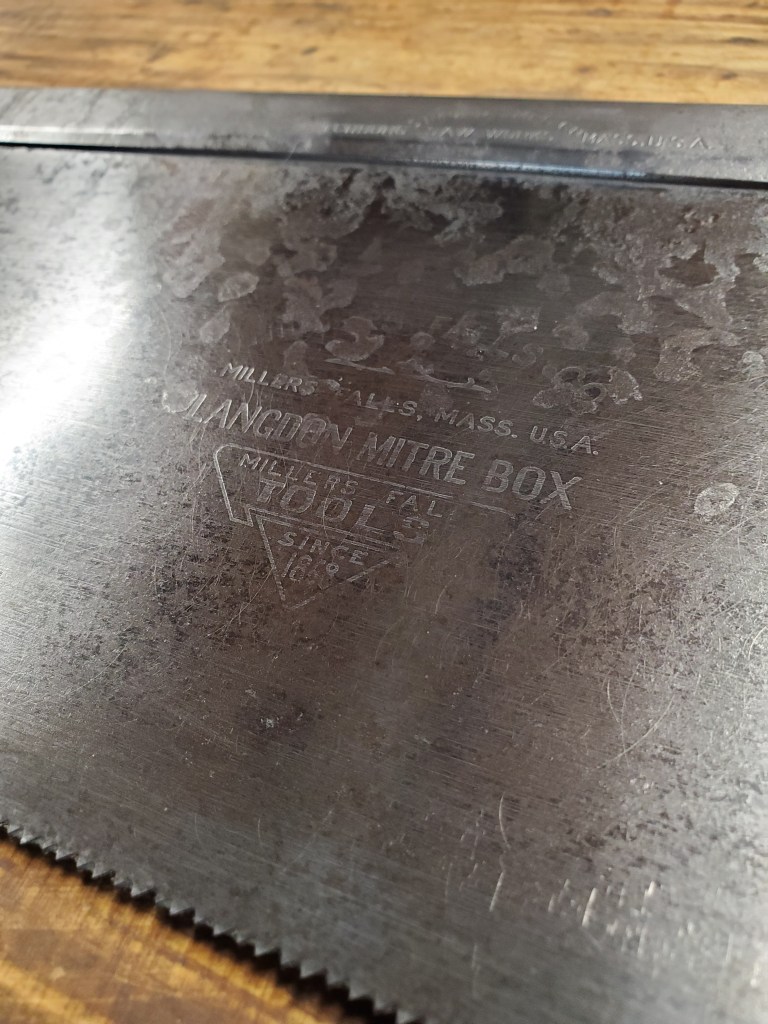

Last month I was fortunate enough to sell my massive Langdon Mitre Box and Disston Saw on eBay after it was listed on the site for over a year.

Just a few weeks before, an article I wrote for The Gristmill, a publication of the Mid-West Tool Collectors Association, was published in their December 2017 issue where I discussed the origin of the tool. A few years back, a member of the MWTCA wrote about the Disston saw, but couldn’t determine if there was ever a miter box that went with it. My article cleared up the controversy. Apparently the guy who bought the miter box from me on eBay, read my article and made me an offer for it. Deciding I had no real need for the tool, I accepted his offer.

I went to u-haul to buy a box, wrapped the miter box and saw in bubble wrap, and carefully packaged both into the shipping box. I took it to UPS and paid for shipping and insurance which cost me $60.00. The girl at the counter told me that UPS insurance only covers damage in shipping if UPS packed the item. Going against my better judgment, I went ahead and bought their insurance anyway since I was the one who packed the tool. In hind sight, I should have just walked out the door and went to USPS to ship it to the buyer.

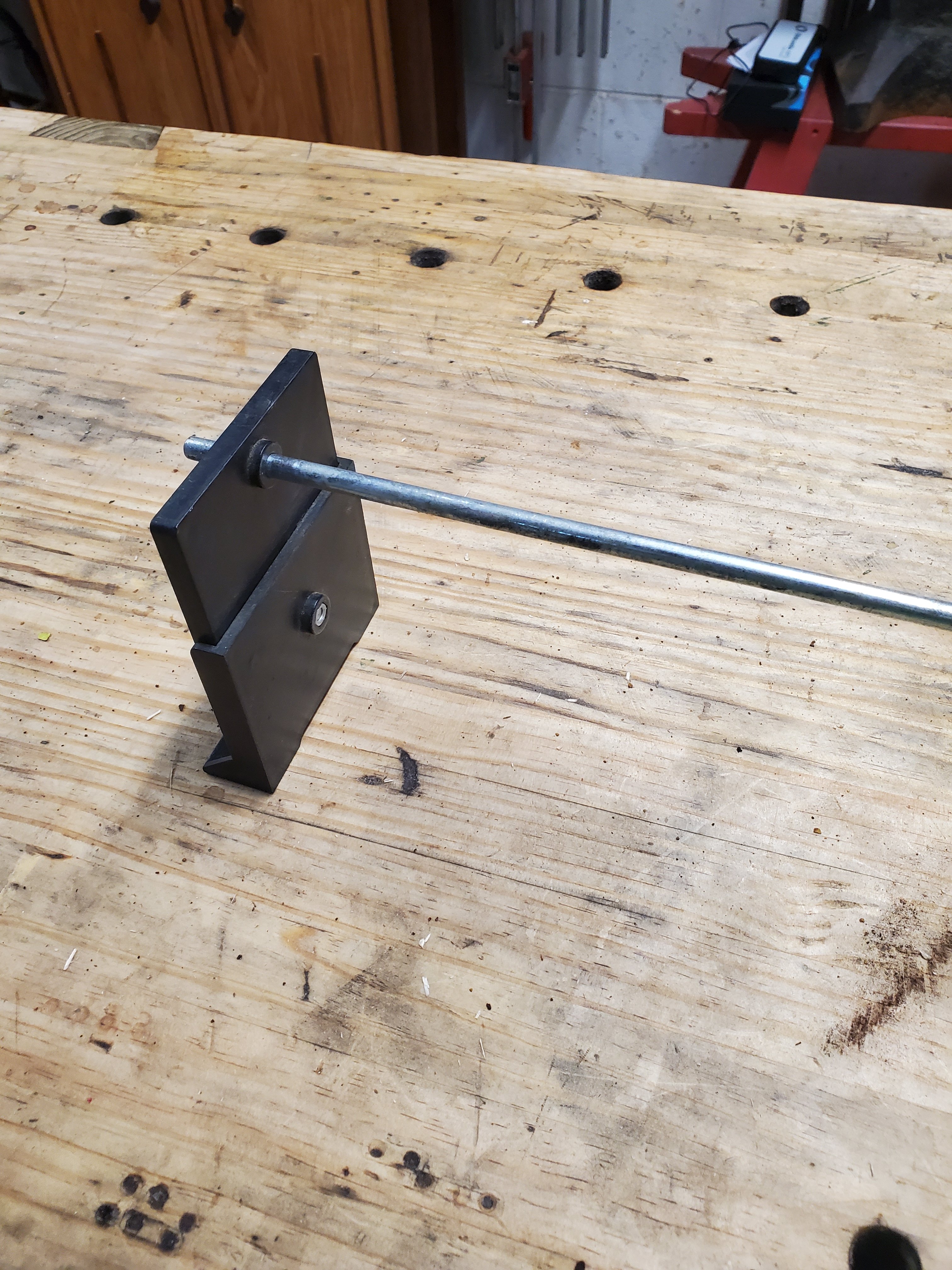

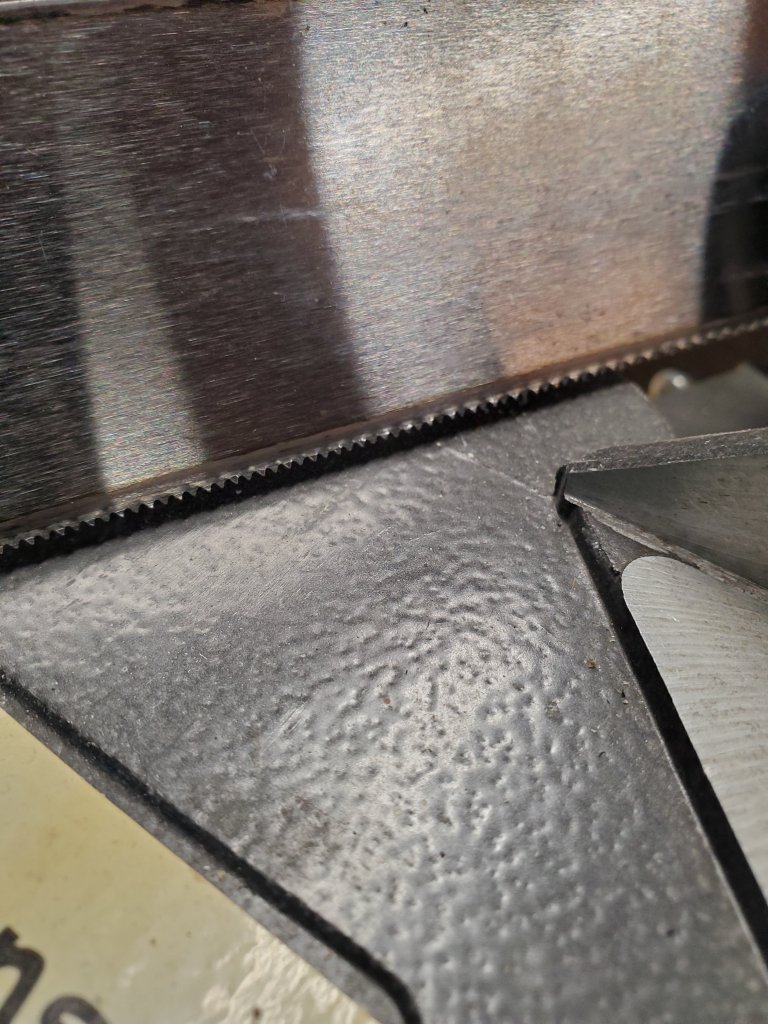

Sure enough a few days later, the buyer contacted me saying that the bottom foot cracked in half during shipping and he wanted to return the tool. I told him to send it back and I’d give him his money back, which he did. When it arrived back to me, the bottom cast iron foot was indeed broken in half. I took some epoxy and glued it back together just so I wouldn’t lose the piece, but the foot is now useless.

The other foot was already broken before I bought the miter box which leaves me with the dilemma; do I try to fix the feet or just leave it be? If I try to fix them, how do I do it? I assume I could make a sand casting of the foot and make two identical feet from the casting, installing them back onto the miter box but, I don’t know how to make a casting as I’ve never tried that before. Additionally, I really don’t want to pay someone to make them for me. Even if I did make new feet, they wouldn’t be original and may detract from the value of the tool. I think my best bet is to find another Langdon miter box for parts and take the feet off that one. They may work as long as the depth of the boxes are the same.

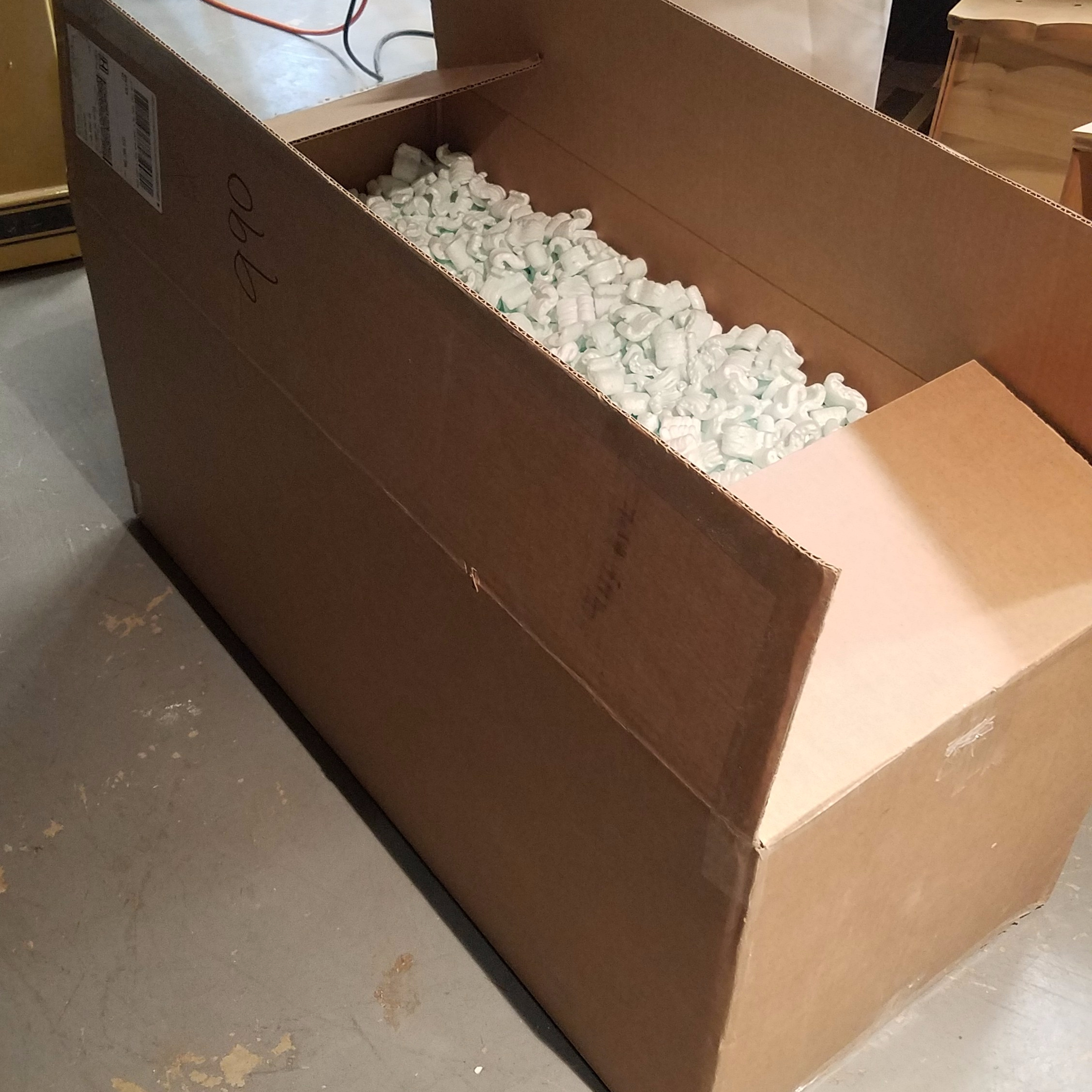

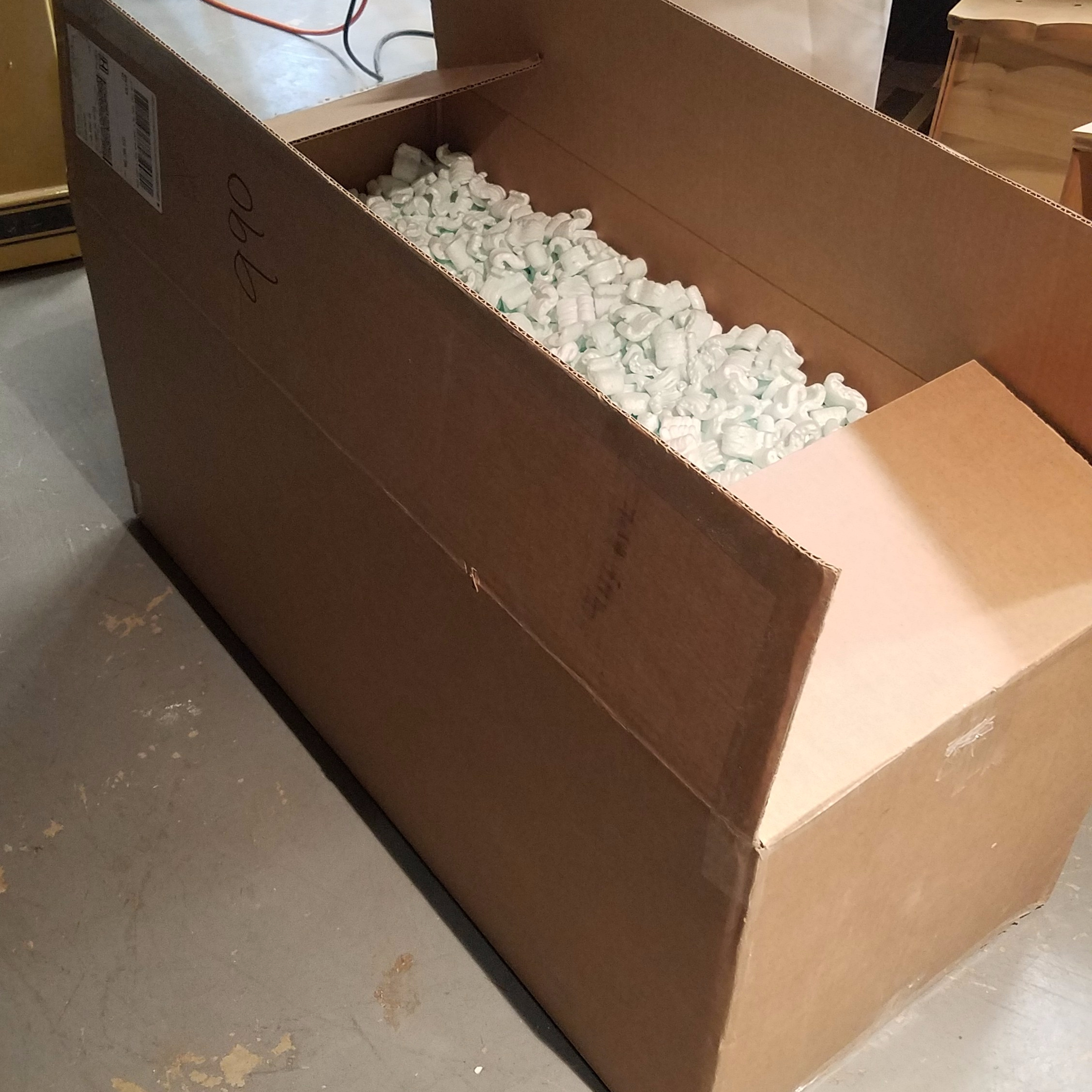

I wish I had this box to begin with. The buyer of the saw did a much better job shipping it back than I did shipping it out. He had a perfect fitting box with a bunch of packaging peanuts inside.

Even the saw was well packed up. I’m glad the saw was never damaged in the shipping as that is what has the most value. I thought about just selling the saw by itself, but I know that’s not the right thing to do as it really needs to be with the miter box it was created for. As far as I know, there are no other miter box and saw combo like this around as they are truly a one of a kind tool. What do I do?