A couple of weeks ago, I had the opportunity to attend the tool auction of Jim “Rooster” Brown. I knew Jim a little bit. He always helped out the Amish Tool Auction in Adams Co Ohio every 4th of July. I went to that auction every year for over fifteen years, and it was always something I looked forward to every year. Jim would help out the auctioneer Hess Auction Co as they sold Hostetler’s tools. I would always end up with a boatload of tools. So much so that one year, my Mom got mad at me for all the money I spent (about $500) when I came home with my loot.

Since it was an auction, I never spent too much time talking to Jim because he was too busy holding up and handing out tools during the auction but when I did talk to him he was a super nice guy. I remember one year, a Stanley No 444 Dovetail Plane came up for sale, and I ended up winning it for $200. Jim yelled out, “He stole it!” Everyone laughed, but I was happy that I did indeed steal it. I owned that plane for many years until I had to sell it due to being unemployed after losing my job.

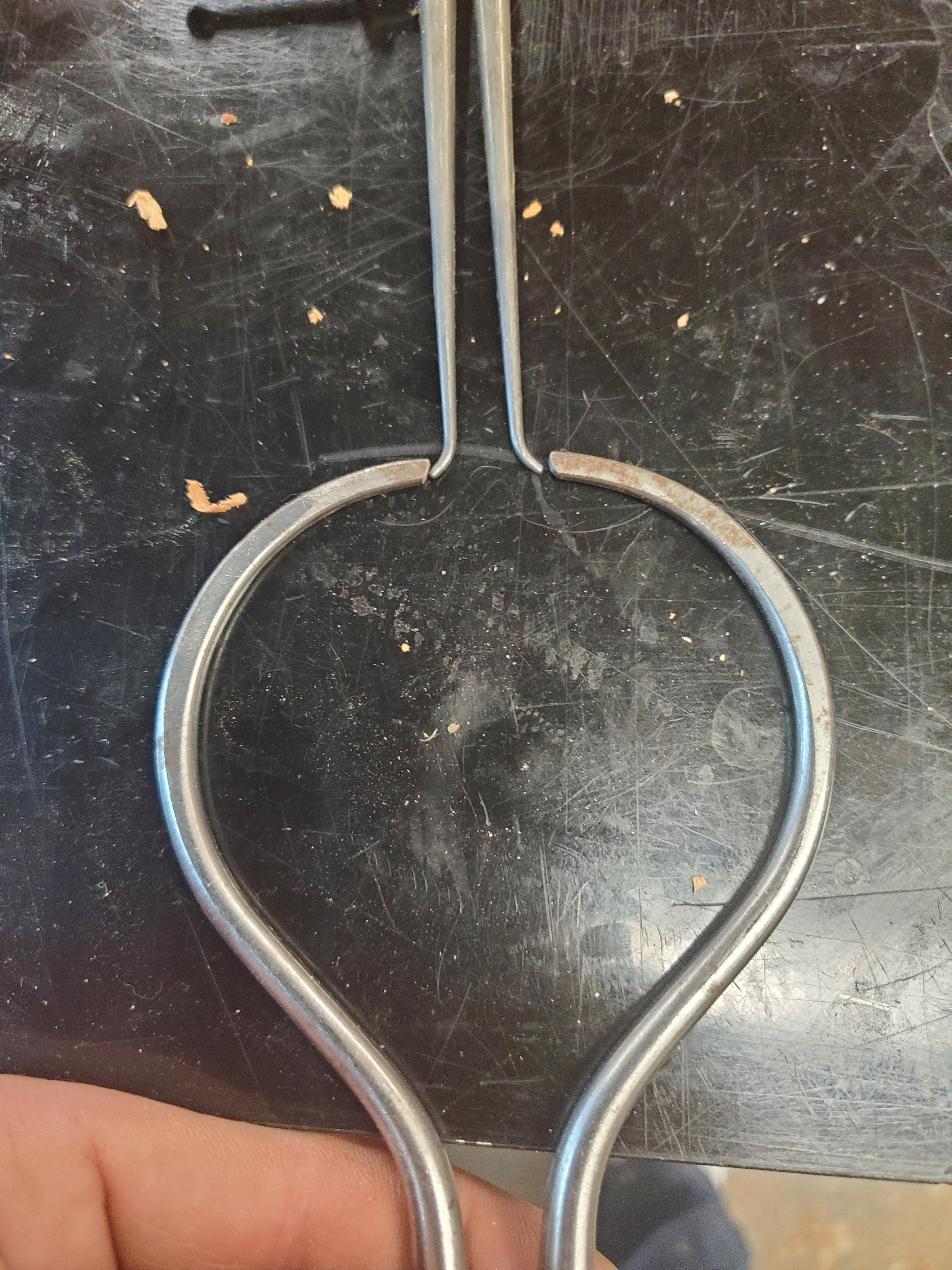

Jim was a collector of Ohio made tools. He had thousands of them after collecting for decades. His collection consisted of hundreds of molding planes, cooper tools, axes, and saws. The first part of the auction was all of his axes, so I had time to look around and examine all the woodworking tools. I couldn’t believe what I was looking at.

Dozens of panel raiser planes, multiple scroll saws, cooper jointer planes, dozens of plow planes, and several tool boxes full of tools that sold as a complete set.

There was a Stanley No 1 plane that sold for $1450.00, and this panther saw that sold for $2625.00. I’ve never seen one in person, and I doubt I ever will again. Some of us thought that the winner overpaid, but one just recently sold for $3500.00.

This Ohio Tool Center Wheel Ivory Tip Plow Plane sold for $2700. The gentleman who won the bid was a personal friend of Jim’s, and he would show it to him every time he visited his home. He was ecstatic that he won his friends favorite plane.

This workbench sold for over $1400.00. I hope it won’t become a kitchen island but you never know these days. lol

This was Jim’s obituary. He worked for the post office for 30 years and was a founding member of the Ohio Tool Collectors.

During the auction, I started to get more involved and bid on the tools. Some of the hand planes I wanted went a little too high for me as a couple of Stanley No 2’s sold for $300 each. At first, I didn’t think I’d win anything, but about halfway through, things started to heat up for me. When they got to the table with all his panel raiser planes, they sold “Choice” off the table. After a couple of rounds, the auctioneer sold all the planes on the table at once. I thought to myself, “Holy shit,” so I got in view of the auctioneer and kept bidding. By the time the bidding ended, I ended up winning all the planes on the table (about 25) for a few hundred dollars. Then, a few minutes later, it happened again, and I ended up buying a second table full of planes for one money. After that, it was full go for me as I was bidding and winning multiple lots.

In the end, this is what I ended up winning. A total of 166 tools. The most tools I ever won and the most money I ever spent at an auction. But boy, did I have fun!

When I got home, I wrote in my book everything I won and what I paid for each tool. I could hear Jim call down from Heaven. “He stole it!”