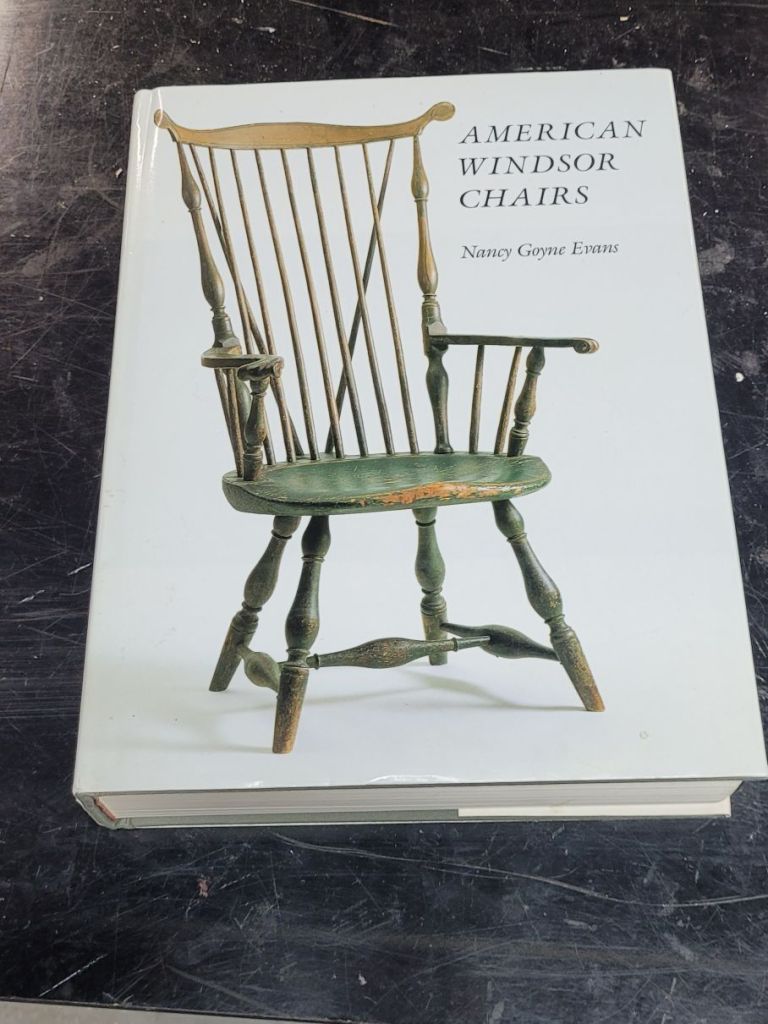

Several months ago, I was reading a post on the Lost Art Press, and someone asked Chris Schwarz which book on Windsor chairs he thought was the best. Chris mentioned American Windsor Chairs and said it’s worth getting if you can find it cheap enough. Curious, I checked Amazon and saw one was for sale for $300. Then I checked eBay and saw one seller was asking $40 plus shipping, so I jumped on it.

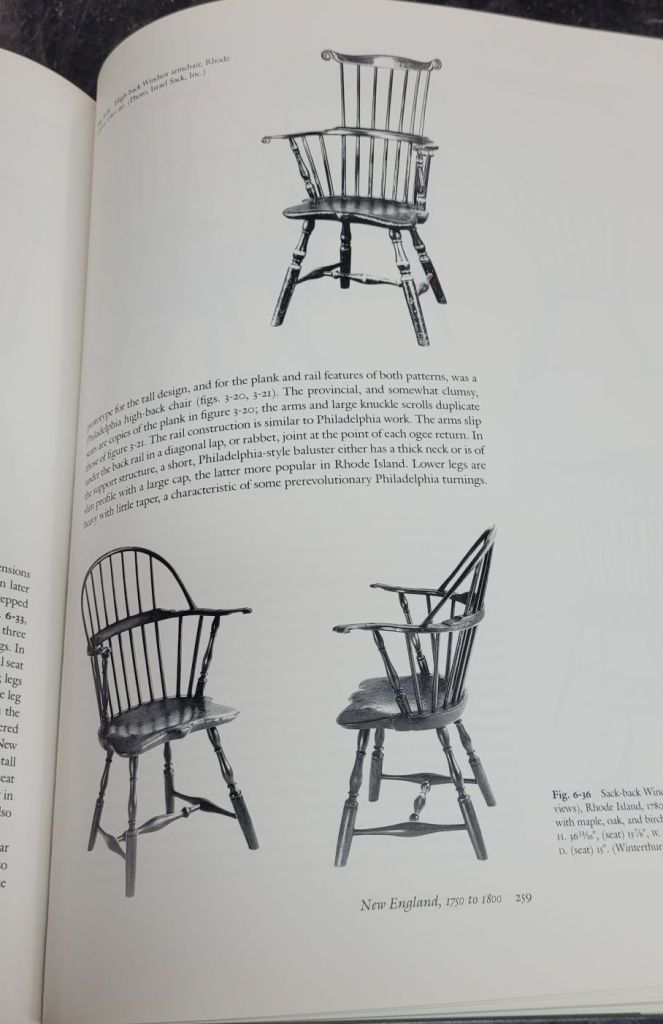

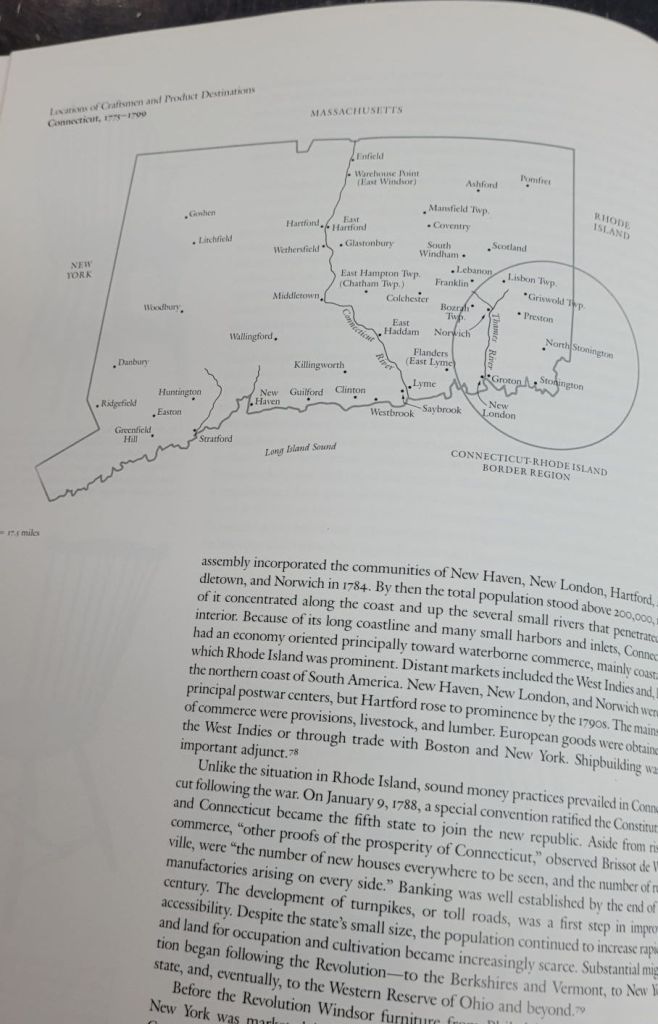

Written by Nancy Goyne Evans, the book is over 700 pages with 1000 illustrations of chairs of various makers. The book starts with the classic European design and how the chairs evolved in America with first handcrafted chairs to mass-produced units in the 1850s. The book is categorized by geographic region and describes the differences in Windsor chairs in different regions of the country. It’s extremely detailed with stories about some of the makers and their business practices. If you have a passion for Windsor chairs and their designs, then this a must-have book you need to own.

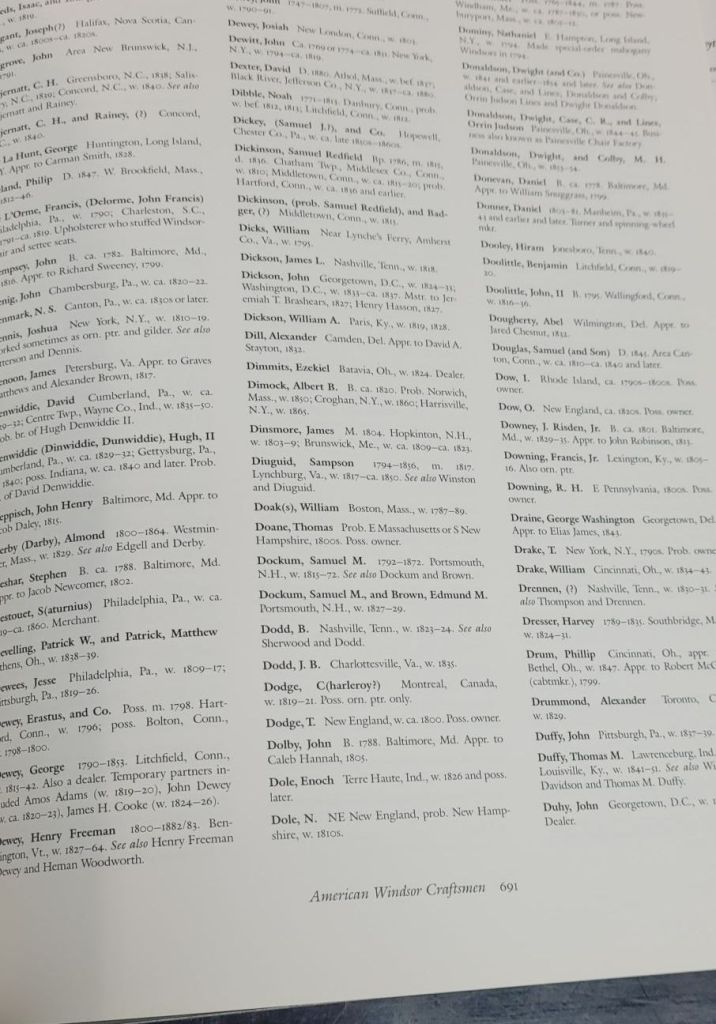

In the back of the book, there are reference pages where it lists the chair makers and the time of their business. Simply look up their name and determine where and when the chair was made. It’s an excellent reference book you’ll enjoy owning if you’re lucky enough to find one at a reasonable price.

If you own a Windsor chair and would like to know when it was made, drop me a comment, and I’ll look it up and see if I can find more information for you.